Your Space frame chassis design calculations images are available in this site. Space frame chassis design calculations are a topic that is being searched for and liked by netizens now. You can Get the Space frame chassis design calculations files here. Find and Download all royalty-free vectors.

If you’re searching for space frame chassis design calculations pictures information connected with to the space frame chassis design calculations topic, you have pay a visit to the right site. Our website always provides you with hints for viewing the highest quality video and image content, please kindly search and find more enlightening video articles and images that match your interests.

Space Frame Chassis Design Calculations. Race-Proven Strength Balance and Safety. Space frame chassis design calculations The strategy on positioning spaceframe number. 222 Space Frame Chassis. This model examines the frame and overall chassis torsional stiffness relative to the suspension spring and anti-roll bar rates.

An Example Of Space Frame Race Car Chassis Structure Based On Formula Download Scientific Diagram From researchgate.net

An Example Of Space Frame Race Car Chassis Structure Based On Formula Download Scientific Diagram From researchgate.net

In this first part of the chassis build we cover the design of the chassis space-frame and build the chassis forward of the firewallHow to Build a Racing C. Built from the foundation of the proven Mk4 chassis the modified Challenge Car chassis meets SCCA GT1 design criteria and is approved for. If you are a person who plans to use your car for more than an occasional open-track day then this chassis kit was designed for you. A finite element model is next. The simple model in Figure 1 shows how the chassis should be constrained green arrows given a bump load red arrow. The design is as the name suggest similar to a ladder.

The principle of spaceframe design is to use triangulation of the tubes to create a rigid structure.

Race-Proven Strength Balance and Safety. Table 1 shows the minimum tubing requirement for chassis members used in our design. An untriangulated box One missing its sides is easily warped. In this first part of the chassis build we cover the design of the chassis space-frame and build the chassis forward of the firewallHow to Build a Racing C. Space frame chassis design calculations The strategy on positioning spaceframe number. AHS Advanced High Strength Steel - a specialized steel alloy designed to be stronger than standard steel.

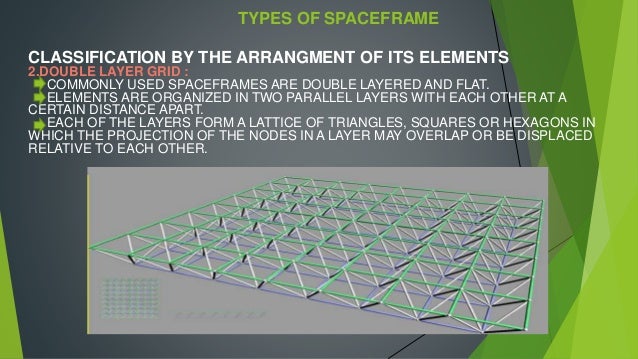

Source: slideshare.net

Source: slideshare.net

The simple model in Figure 1 shows how the chassis should be constrained green arrows given a bump load red arrow. Table 1 shows the minimum tubing requirement for chassis members used in our design. The project concerns rationalizing Chassis calculations for use in truck Frame design. The simple model in Figure 1 shows how the chassis should be constrained green arrows given a bump load red arrow. An untriangulated box One missing its sides is easily warped.

Source: researchgate.net

Source: researchgate.net

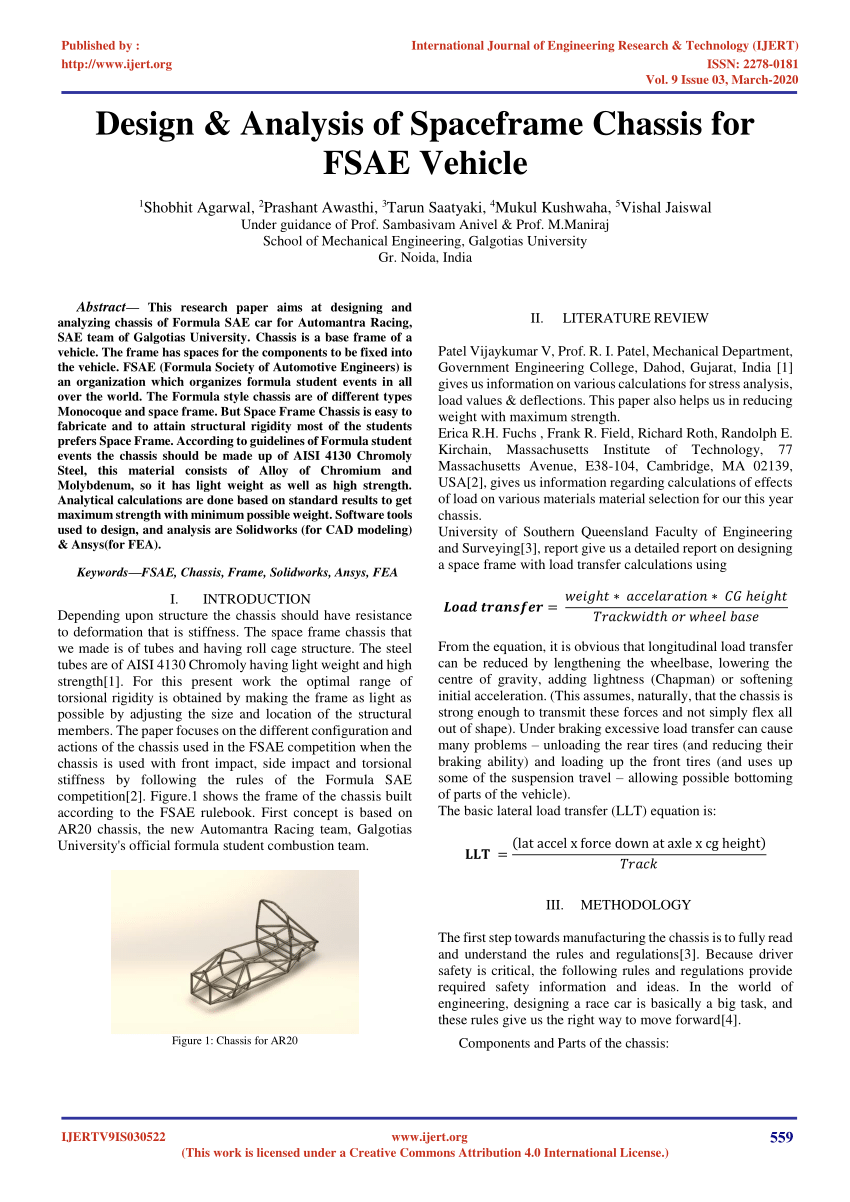

An untriangulated box One missing its sides is easily warped. Left Rear Constrained in X Y and Z directions. A finite element model is next. There are five systems which are fixed in both size and position. 3 report give us a detailed report on designing a space frame with load transfer calculations using ℎ ℎ ℎ ℎ ℎFrom the equation it is obvious that longitudinal load.

Source: ar.pinterest.com

Source: ar.pinterest.com

Strain curve of ductile materialDesign manufacturing and verification of a steel tube spaceframe. Load transfer 136 300 03 1786 Load transfer 685kg transfers to the front of the car due to braking. An untriangulated box One missing its sides is easily warped. Space frame chassis design calculations The strategy on positioning spaceframe number. There are two longitudinal rails running the length of the vehicle which are connected together by several lateral and cross braces.

Source: formula1-dictionary.net

Source: formula1-dictionary.net

A space frame with load transfer calculations using 𝑳𝒐𝒂𝒅 𝒕𝒓𝒂𝒏𝒔𝒇𝒆𝒓 𝑤𝑒𝑖𝑔ℎ𝑡 𝑎𝑐𝑐𝑒𝑙𝑎𝑟𝑎𝑡𝑖𝑜𝑛 𝐶𝐺. AHS Advanced High Strength Steel - a specialized steel alloy designed to be stronger than standard steel. 34 Material property steel must not be lower than the following Bending and buckling strength calculations. The subject for analysis is a six-wheeled articulated truck and the load cases under study is Lateral Loading Frame Torsion and Vertical Load on Kingpin. The carbon fibre monocoque orange The drivetrain fixed in z and x direction green The suspension geometry pink The spring-damper system blue 7.

Source: researchgate.net

Source: researchgate.net

A finite element model is next. Left Rear Constrained in X Y and Z directions. The subject for analysis is a six-wheeled articulated truck and the load cases under study is Lateral Loading Frame Torsion and Vertical Load on Kingpin. This means lighter weight higher tensile strength and superior environmental resistance. Race-Proven Strength Balance and Safety.

Source: jvejournals.com

Source: jvejournals.com

The upper face of the top member is fixed in all degrees of freedom and the lower section has a force of 1kN applied uniformly to its lower face in the X direction. This model examines the frame and overall chassis torsional stiffness relative to the suspension spring and anti-roll bar rates. An untriangulated box One missing its sides is easily warped. A finite element model is next. If you are a person who plans to use your car for more than an occasional open-track day then this chassis kit was designed for you.

Space frame is a combination of individual beamcolumn elements that resists loadings by a combination of bending axial member forces and transverse shear forces and. 222 Space Frame Chassis. Left Rear Constrained in X Y and Z directions. 34 Material property steel must not be lower than the following Bending and buckling strength calculations. The test model is a 500mm square arrangement of pipe sections constructed from the square 254x254x14mm tubing used in the chassis.

This model examines the frame and overall chassis torsional stiffness relative to the suspension spring and anti-roll bar rates. Space frame is a combination of individual beamcolumn elements that resists loadings by a combination of bending axial member forces and transverse shear forces and. 222 Space Frame Chassis. The principle of spaceframe design is to use triangulation of the tubes to create a rigid structure. This model examines the frame and overall chassis torsional stiffness relative to the suspension spring and anti-roll bar rates.

In this first part of the chassis build we cover the design of the chassis space-frame and build the chassis forward of the firewallHow to Build a Racing C. If you are a person who plans to use your car for more than an occasional open-track day then this chassis kit was designed for you. The design is as the name suggest similar to a ladder. Left Rear Constrained in X Y and Z directions. Race-Proven Strength Balance and Safety.

Source: formula1-dictionary.net

Source: formula1-dictionary.net

The test model is a 500mm square arrangement of pipe sections constructed from the square 254x254x14mm tubing used in the chassis. Strain curve of ductile materialDesign manufacturing and verification of a steel tube spaceframe. The simple model in Figure 1 shows how the chassis should be constrained green arrows given a bump load red arrow. See more ideas about space frame chassis fabrication car frames. Race-Proven Strength Balance and Safety.

Source: jvejournals.com

Source: jvejournals.com

This model examines the frame and overall chassis torsional stiffness relative to the suspension spring and anti-roll bar rates. Built from the foundation of the proven Mk4 chassis the modified Challenge Car chassis meets SCCA GT1 design criteria and is approved for. 34 Material property steel must not be lower than the following Bending and buckling strength calculations. In this first part of the chassis build we cover the design of the chassis space-frame and build the chassis forward of the firewallHow to Build a Racing C. A finite element model is next.

Developed to determine targets for frame and overall chassis stiffness. Diagrams SF2 and SF3 below show how triangulation is used to rigidize a structure. Table 1 shows the minimum tubing requirement for chassis members used in our design. The principle of spaceframe design is to use triangulation of the tubes to create a rigid structure. Built from the foundation of the proven Mk4 chassis the modified Challenge Car chassis meets SCCA GT1 design criteria and is approved for.

Source: slideshare.net

Source: slideshare.net

The design is as the name suggest similar to a ladder. The carbon fibre monocoque orange The drivetrain fixed in z and x direction green The suspension geometry pink The spring-damper system blue 7. This is a Masters Thesis report of a project carried out at Scania AB in S odert alje. All chassis types except semi-space frame can be built using corrosion resistant steel. A space frame with load transfer calculations using 𝑳𝒐𝒂𝒅 𝒕𝒓𝒂𝒏𝒔𝒇𝒆𝒓 𝑤𝑒𝑖𝑔ℎ𝑡 𝑎𝑐𝑐𝑒𝑙𝑎𝑟𝑎𝑡𝑖𝑜𝑛 𝐶𝐺.

The upper face of the top member is fixed in all degrees of freedom and the lower section has a force of 1kN applied uniformly to its lower face in the X direction. A finite element model is next. The subject for analysis is a six-wheeled articulated truck and the load cases under study is Lateral Loading Frame Torsion and Vertical Load on Kingpin. A space frame with load transfer calculations using 𝑳𝒐𝒂𝒅 𝒕𝒓𝒂𝒏𝒔𝒇𝒆𝒓 𝑤𝑒𝑖𝑔ℎ𝑡 𝑎𝑐𝑐𝑒𝑙𝑎𝑟𝑎𝑡𝑖𝑜𝑛 𝐶𝐺. Space frame is a combination of individual beamcolumn elements that resists loadings by a combination of bending axial member forces and transverse shear forces and.

Source: pinterest.com

Source: pinterest.com

A space frame with load transfer calculations using 𝑳 𝒂 𝒂 𝑤 𝑖𝑔ℎ P N 𝑖 K J 𝐶𝐺 ℎ 𝑖𝑔ℎ P. There are two longitudinal rails running the length of the vehicle which are connected together by several lateral and cross braces. 222 Space Frame Chassis. The global size and position are referred to in figure 3. Diagrams SF2 and SF3 below show how triangulation is used to rigidize a structure.

Source: researchgate.net

Source: researchgate.net

The design is as the name suggest similar to a ladder. All chassis types except semi-space frame can be built using corrosion resistant steel. A space frame with load transfer calculations using 𝑳 𝒂 𝒂 𝑤 𝑖𝑔ℎ P N 𝑖 K J 𝐶𝐺 ℎ 𝑖𝑔ℎ P. The simple model in Figure 1 shows how the chassis should be constrained green arrows given a bump load red arrow. There are two longitudinal rails running the length of the vehicle which are connected together by several lateral and cross braces.

Source: researchgate.net

Source: researchgate.net

Youngs Modulus E 200. The principle of spaceframe design is to use triangulation of the tubes to create a rigid structure. The design is as the name suggest similar to a ladder. Space frame chassis design calculations The strategy on positioning spaceframe number. The project concerns rationalizing Chassis calculations for use in truck Frame design.

Source: researchgate.net

Source: researchgate.net

Left Rear Constrained in X Y and Z directions. All chassis types except semi-space frame can be built using corrosion resistant steel. A complete analysis of a space frame chassis by using carbon fiber is carried out so as to compare it with steel and to optimize it by reducing its cross section so that the overall weight can be lowered ultimately ensuing improved performance. The project concerns rationalizing Chassis calculations for use in truck Frame design. Built from the foundation of the proven Mk4 chassis the modified Challenge Car chassis meets SCCA GT1 design criteria and is approved for.

This site is an open community for users to do sharing their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site helpful, please support us by sharing this posts to your favorite social media accounts like Facebook, Instagram and so on or you can also save this blog page with the title space frame chassis design calculations by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.